All of the lifting devices of Dotec meet the standards of ergonomics, working environment, safety and efficiency. With a unique integration of mechanical, electric, and pneumatic features which minimises maintenance and maximises your process.

Flexible packaging

Dotec handlers are operational worldwide, many in production facilities where the food is freshly produced. Flexible packaging includes bags, pouches, shrink films, tubes, sleeves, and carded packaging. All these products are processed by end users of finished rolls for which Dotec has supplied multiple solutions mainly in 24/7 production environments.

Hygiene nonwoven

The nonwoven roll handling solutions of Dotec provide a high variety of applications for many types of nonwoven materials. Dotec has a long history of delivering solutions to the baby- feminine- and adult care product lines. Also, wipes and household goods manufacturers are part of the Dotec user family.

Yarn & textile

Dotec’s Roll handlers for yarn and fabrics have been developed in real practice and for real practice. Wide and heavy rolls handled with Probe Type solutions, creel lines loaded and unloaded with fast and light lifting & turning devices.

Logistics

Dotec has made a big change in the efficiency of processes in distribution centers. Now it is up to you whether a Dotec can make a positive difference in your distribution process.

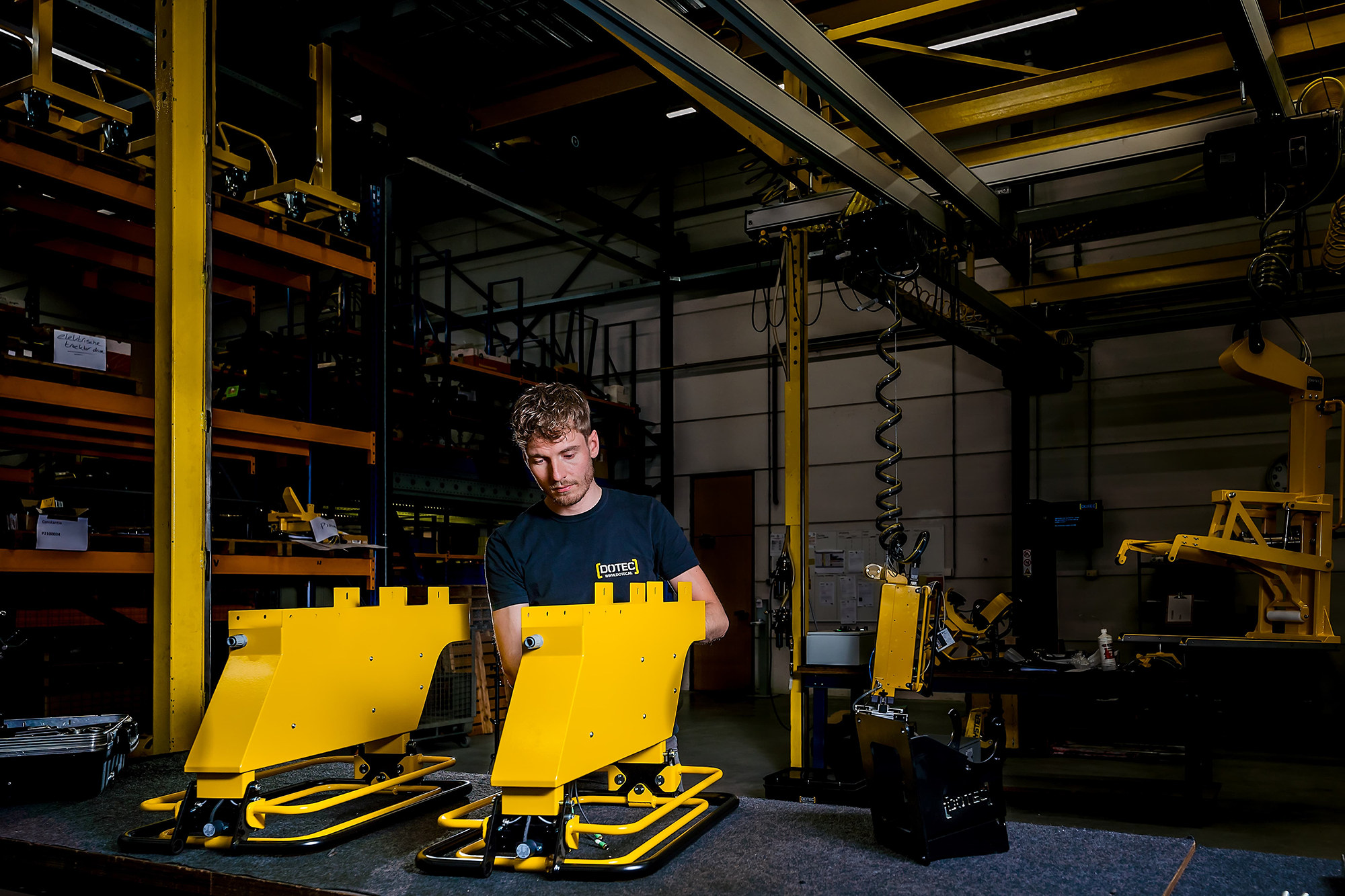

Industrial parts handling

Within the manufacturing process many parts need to be lifted in order to complete the production of a product. Dotec makes sure this placement of parts is more ergonomic and operates in a smooth working flow. Dotec contributes to your production process and makes it more ergonomic, safer and generates more output.

The Dotec feeling

Dotec, your Friendly LiftAssist

The Dotec LiftAssist has very specific characteristics that are based on ease of operation, speed of handling and ergonomics. It has a very short learning curve. Everything can be controlled by a finger touch which makes it very easy to work with. That is why it is called The Friendly LiftAssist.

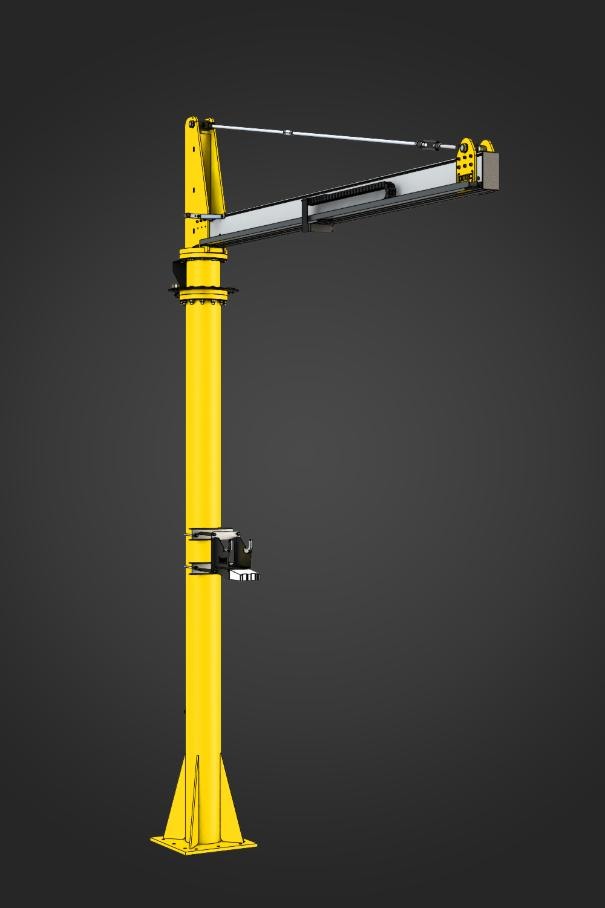

Lifting device infrastructure

With a Friendly liftassist of Dotec comes its very own infrastructure, to maximise the performance of your lifting solution process. Depending on several factors the decision is made whether a rail system or a jib crane is most suitable for your process.

A rail system is more suitable for a smooth, clean and corrosive free surface. The enclosed rail design reduces the accumulation of dirt and grime on the internal running surface, thus reducing rolling effort.

Jib cranes are more suitable for short transfer processes. They provide a comfortable and ergonomic movement and smooth and free 360 rotation. With an integrated parking brake it secures a safe way of parking the handler, when it is not in use.

The Dotec System

Dotec LiftAssists have very specific characteristics that are based on ease of operation, speed of work and ergonomics. The learning curve is only 10 minutes, and handling becomes a pleasure.